When it comes to selecting the right quick couplings for your hydraulic or fluid systems, understanding the thread type is crucial. One of the most commonly used thread types in quick couplings is the National Pipe Tapered (NPT) thread. In this blog post, we will dive into what NPT threads are, the dimensions of male and female NPT threads, and how this thread type ensures a secure and leak-free connection in various industries.

What Are NPT Threads?

NPT (National Pipe Tapered) threads are commonly used in the United States for joining pipes and fittings. The defining feature of NPT threads is their tapered shape. The threads are cut at an angle of 1°47′ (0.75 in/ft or 62.5 mm/m), which means that as the male and female parts of the thread are tightened, the threads compress against each other, creating a tight seal.

This unique thread taper ensures that the connection becomes increasingly tight as you tighten the fitting, preventing leaks without the need for additional sealing materials in many cases. However, in some applications, a thread sealant may still be used for extra assurance.

The Structure of NPT Threads

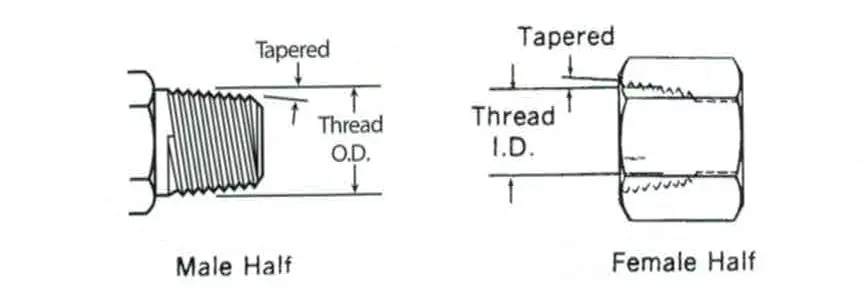

NPT threads consist of two main components: male threads (on the pipe) and female threads (on the fitting). The sealing process occurs as the external (male) thread and internal (female) thread mesh together and compress.

- External Thread (Pipe): The male end, which is typically the pipe, has tapered threads that tighten into the female fitting.

- Internal Thread (Fitting): The female fitting has complementary tapered threads that match the male threads.

Key Dimensions for NPT Threads

Understanding the exact dimensions for both male and female NPT threads is critical for ensuring the right fit and a secure, leak-free connection. Here’s a breakdown of the essential dimensions and what they mean:

Common NPT Thread Dimensions (Male & Female)

- Pitch (P): The number of threads per inch (TPI). This is critical for determining the thread’s tightness and how the two parts will mesh.

- Thread Taper Angle (ß): NPT threads have a taper angle of 1°47′ (or 0.75 in/ft). This is the angle at which the threads taper from the large end to the small end.

- Height of Thread (H): This is the height of the theoretical V-shaped thread profile.

- Length of Hand-Tight Engagement (L1): This is the maximum distance that the male and female threads can be turned together by hand. When tightening, this engagement length is crucial to achieve the initial seal.

Male Thread (Pipe) Dimensions

For external threads (pipes), key dimensions include:

- Pipe OD (D): The outer diameter of the pipe.

- Pitch Diameter at Pipe’s End (E0): The diameter at the pipe’s end, factoring in the pitch.

- Minor Diameter at Pipe’s End (K0): The smallest diameter of the pipe’s thread.

- Length of Last Complete Thread (L5): The length of the last thread before the taper becomes incomplete.

- Length of Last Useful Thread (L2): The length up to the point where the taper starts to render the thread unusable.

Female Thread (Fitting) Dimensions

For internal threads (fittings), the key dimensions are:

- Pitch Diameter at Fitting’s End (E1): The diameter at the fitting’s end.

- Wrenching Allowance (L3): This is the additional distance that the fitting should be tightened with a wrench to form a seal.

- Pitch Diameter at L3 (E3): The diameter at the wrenching allowance.

Basic Thread Dimensions for NPT

Here’s a quick reference chart for common NPT sizes:

Male NPT threads are designed to screw into female NPT threads. The critical dimension for male NPT threads is the thread diameter, followed by the taper angle and the pitch.

Here’s a breakdown of the typical dimensions for male NPT threads:

| Thread Size | Major Diameter(inches) | Minor Diameter(inches) | Pitch(Threads per inch) | Taper Angle |

|---|---|---|---|---|

| 1/8″ | 0.405 | 0.337 | 27 | 1° 47′ |

| 1/4″ | 0.540 | 0.472 | 18 | 1° 47′ |

| 3/8″ | 0.675 | 0.595 | 18 | 1° 47′ |

| 1/2″ | 0.840 | 0.760 | 14 | 1° 47′ |

| 3/4″ | 1.050 | 0.970 | 14 | 1° 47′ |

| 1″ | 1.315 | 1.235 | 11 | 1° 47′ |

| 1-1/4″ | 1.660 | 1.580 | 11 | 1° 47′ |

| 1-1/2″ | 1.900 | 1.820 | 11 | 1° 47′ |

- Major diameter: This is the outer diameter of the thread and is crucial when selecting the correct size coupling.

- Minor diameter: This is the inner diameter at the root of the thread, ensuring that the coupling fits into the female counterpart.

- Pitch: Refers to the number of threads per inch (TPI), which ensures that the male and female threads engage properly.

- Taper angle: The angle at which the threads taper, ensuring a secure, tight fit when connected.

Female NPT Thread Dimensions

Female NPT threads are designed to receive the male NPT threads. The dimensions of female NPT threads are similar to the male threads but are designed to fit around the external threads of the male coupling. Here’s a breakdown of the typical dimensions for female NPT threads:

| Thread Size | Major Diameter(inches) | Minor Diameter(inches) | Pitch(Threads per inch) | Taper Angle |

|---|---|---|---|---|

| 1/8″ | 0.405 | 0.337 | 27 | 1° 47′ |

| 1/4″ | 0.540 | 0.472 | 18 | 1° 47′ |

| 3/8″ | 0.675 | 0.595 | 18 | 1° 47′ |

| 1/2″ | 0.840 | 0.760 | 14 | 1° 47′ |

| 3/4″ | 1.050 | 0.970 | 14 | 1° 47′ |

| 1″ | 1.315 | 1.235 | 11 | 1° 47′ |

| 1-1/4″ | 1.660 | 1.580 | 11 | 1° 47′ |

| 1-1/2″ | 1.900 | 1.820 | 11 | 1° 47′ |

As you can see, the female NPT thread dimensions are almost identical to the male NPT threads, but they are designed to fit snugly around the male threads, ensuring a secure connection. The same pitch and taper angle apply, which makes the coupling connection robust and leak-resistant.

Key Benefits of NPT Threads in Quick Couplings

- Leak-Free Sealing: The tapered design of NPT threads ensures a tight, leak-free seal, making them perfect for fluid and gas systems.

- Durability: NPT threads are robust and can handle high pressure and harsh environments, making them suitable for industrial and agricultural applications.

- Wide Availability: NPT-threaded couplings are widely available and compatible with various other pipe fittings, making them easy to integrate into existing systems.

Conclusion

Understanding NPT threads and their dimensions is essential for selecting the right quick coupling for your hydraulic or fluid handling system. With their leak-tight seal, durability, and easy availability, NPT threads are a top choice for many industries. By knowing the male and female NPT thread dimensions, you can ensure a proper and reliable connection for your system.

If you have any questions or need help selecting the right NPT-threaded quick couplings, feel free to contact us!