For those of us in the quick coupling industry, understanding the various fitting types and thread standards is crucial. Among the most common in hydraulic systems are JIC (Joint Industry Council) 37-degree flare fittings. This post will introduce you to the world of JIC fittings, explaining their key features, the meaning behind their size designations like the #12, and their relationship with UNF threads.

What are JIC 37-Degree Fittings?

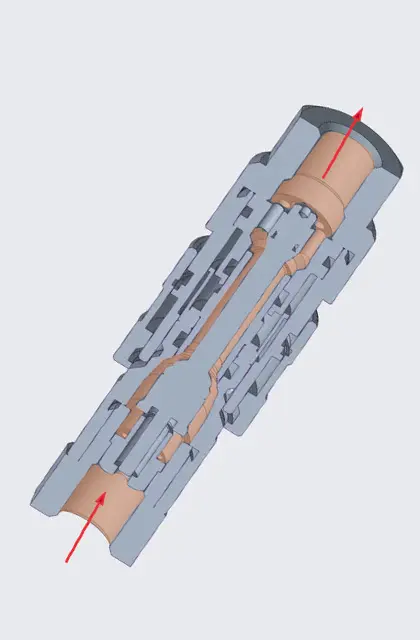

JIC fittings are a type of flare fitting widely used in fluid power applications, particularly in hydraulic systems. They are easily identifiable by their 37-degree cone-shaped seating surface. The seal is created by the metal-to-metal contact between the flared end of the tube or hose and the cone shape of the fitting when the nut is tightened. This design provides a robust and reliable connection capable of handling high pressures. JIC fittings are standardized under SAE J514.

The JIC Dash Size System: Understanding the #12

One of the initially confusing aspects of JIC fittings can be their size designations, often referred to as “dash sizes.” These numbers, like the #12 in your example, directly relate to the nominal outside diameter (OD) of the tubing the fitting is designed for, expressed in sixteenths of an inch.

So, for a #12 JIC fitting:

- The #12 signifies that the fitting is designed for tubing with a nominal OD of 12/16 of an inch.

- Simplifying the fraction, 12/16 reduces to 3/4 of an inch.

Therefore, a #12 JIC fitting is designed to connect to 3/4″ OD tubing. This dash size system provides a quick and standardized way to identify the intended tube size for a JIC fitting.

UNF Threads: The Backbone of the Connection

While the 37-degree flare provides the seal, the connection is secured by a nut with a Unified National Fine (UNF) thread. UNF threads are a standardized screw thread series with a fine pitch, meaning there are more threads per inch compared to a coarse thread (like UNC – Unified National Coarse). This fine pitch offers several advantages for hydraulic fittings:

- Increased Resistance to Vibration: The finer threads are less likely to loosen under vibration.

- Finer Adjustment: The smaller pitch allows for more precise tightening and control over the clamping force.

- Improved Sealing: The increased number of threads engaged provides a better distribution of force, contributing to a reliable seal.

For each JIC dash size, there is a corresponding standard UNF thread size for the nut and the male half of the fitting. Here is a table of common JIC dash sizes, their corresponding nominal tube OD, and the associated UNF thread specification:

| JIC Dash Size | Nominal Tube OD (inches) | UNF Thread Size |

|---|---|---|

| #2 | 1/8 | 5/16″-24 UNF |

| #3 | 3/16 | 3/8″-24 UNF |

| #4 | 1/4 | 7/16″-20 UNF |

| #5 | 5/16 | 1/2″-20 UNF |

| #6 | 3/8 | 9/16″-18 UNF |

| #8 | 1/2 | 3/4″-16 UNF |

| #10 | 5/8 | 7/8″-14 UNF |

| #12 | 3/4 | 1-1/16″-12 UN |

| #14 | 7/8 | 1-3/16″-12 UN |

| #16 | 1 | 1-5/16″-12 UN |

| #20 | 1-1/4 | 1-5/8″-12 UN |

| #24 | 1-1/2 | 1-7/8″-12 UN |

| #32 | 2 | 2-1/2″-12 UN |

Understanding this relationship between the JIC dash size, the tubing OD, and the specific UNF thread is essential for selecting and mating the correct components in a hydraulic system.

In Conclusion

JIC 37-degree flare fittings are a cornerstone of many hydraulic applications, valued for their reliable sealing and pressure capabilities. The dash size system offers a simple way to identify the intended tube size, with the number directly corresponding to the tube’s OD in sixteenths of an inch. The accompanying UNF threads, with their fine pitch, provide the secure and vibration-resistant connection necessary for high-performance fluid power systems. As quick coupling manufacturers, a thorough understanding of these details allows us to provide our customers with the right solutions for their hydraulic connection needs.