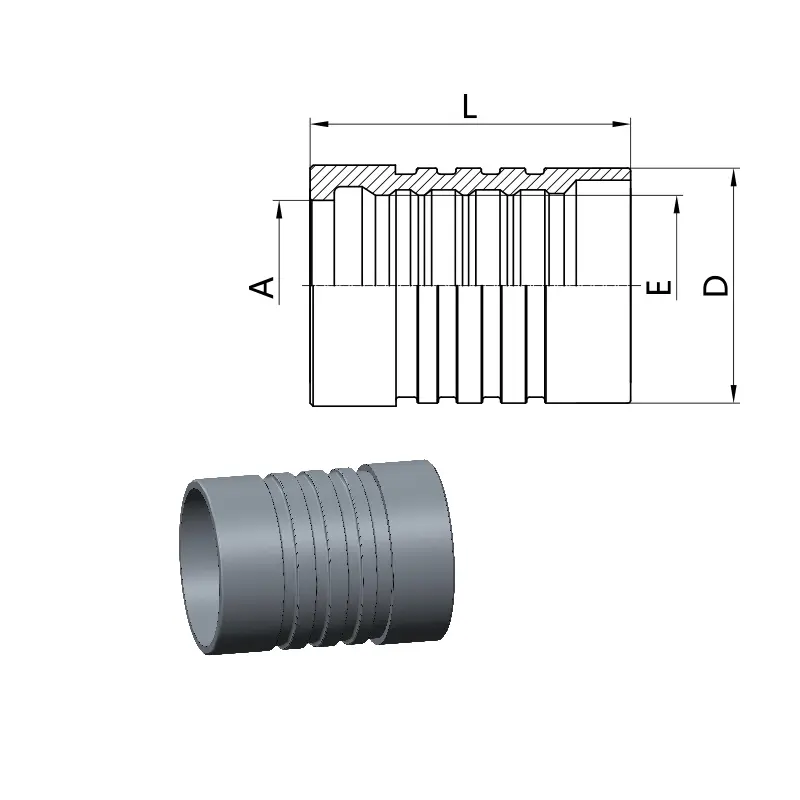

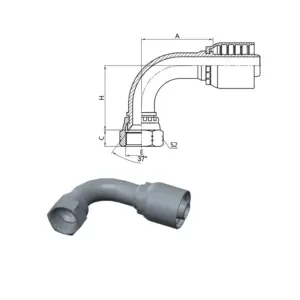

| PARTNO. |

DN |

DASH |

A |

D |

E |

L |

| 00621-12 |

19 |

12 |

28.3 |

39 |

30.2 |

53 |

| 00621-16 |

25 |

16 |

37.4 |

47.2 |

37 |

66 |

| 00621-20 |

32 |

20 |

43.4 |

60 |

49.2 |

88.5 |

| 00621-24 |

38 |

24 |

49.5 |

65.7 |

55.5 |

102 |

| 00621-32 |

51 |

32 |

64.5 |

82.7 |

70.7 |

108 |

Ferrule For SAE100 R13/ R15 Hose (External Skive)

Our ferrules for SAE100 R13 and R15 hydraulic hoses are specially designed for external skive applications, ensuring a secure and durable connection between the hose and the fitting.

Made from high-strength steel, these ferrules are built to handle extremely high-pressure environments, making them perfect for heavy-duty hydraulic systems. They provide excellent hose retention and leak resistance, even under intense working conditions.

Available in multiple sizes to fit DN19 to DN51 hoses, our ferrules are precision-engineered to meet the demanding standards of modern hydraulic operations.

Key Features:

- Designed for SAE100 R13 and R15 hose external skiving

- Heavy-duty steel construction for superior strength and durability

- High-pressure and high-vibration resistance

- Precision-machined for tight, secure hose fitting

- Sizes available for DN19 to DN51 hoses

Applications:

- High-pressure hydraulic systems

- Construction and mining machinery

- Oil and gas industry

- Industrial hydraulic equipment

Specifications:

- Hose Size: DN19 (3/4”) to DN51 (2”)

- External skive type ferrule

- Material: Carbon Steel

Q1, What is a Ferrule?

A ferrule is a metal sleeve used in hydraulic hose assemblies to secure the fitting to the hose.

Q2, What is SAE100 R13 and R15?

-

SAE 100R13

-

A four or six-spiral steel wire reinforced hydraulic hose.

-

Used for extremely high-pressure applications, such as heavy machinery and industrial hydraulic systems.

-

SAE 100R15

Q3, Why a Special Ferrule for R13/R15?

-

R13 and R15 hoses have a thicker outer cover and multi-spiral wire reinforcement, requiring a stronger ferrule with a deep crimping profile.

-

The ferrule ensures a secure, high-pressure-resistant connection between the hose and the fitting.

Q4, Why Do SAE 100R13 and R15 Hoses Require External Skiving?

1. Understanding External Skiving

-

External skiving means removing the outer rubber cover of the hose before crimping the ferrule.

-

This process exposes the steel wire reinforcement layer, allowing for better crimping and grip between the ferrule and the hose.

2. Why Skive R13 & R15 Hoses?

-

R13 and R15 hoses are multi-spiral steel wire reinforced hoses with a thick outer rubber layer.

-

If the ferrule is crimped over the unskived outer cover, the rubber may compress unevenly, reducing crimping effectiveness.

-

External skiving improves the bite of the ferrule, ensuring a secure, high-pressure connection.

3. Benefits of External Skiving

- Better Grip & Retention – The ferrule grips directly onto the steel wire reinforcement, preventing slippage.

- Leak Prevention – Ensures a tighter and more secure crimp for high-pressure applications.

- Stronger Connection – Essential for ultra-high-pressure hydraulic systems that use R13/R15 hoses.

Reviews

There are no reviews yet.