In hydraulic systems, every drop of fluid matters. Whether it’s for safety, environmental protection, cost savings, or system performance, minimizing fluid loss during connection and disconnection is essential. That’s why many professionals in construction, agriculture, forestry, mining, and industrial maintenance prefer flat face quick couplings — they are specifically designed to prevent fluid loss.

What Is Fluid Loss in Hydraulic Couplings?

Fluid loss occurs when hydraulic fluid escapes from a system during the connection or disconnection of hoses, tools, or machinery components. This happens especially in older or traditional coupling styles — such as poppet or ball valve couplings (ISO A, ISO B, or ISO 5675) — where the internal valve doesn’t seal fully until the connection is complete.

When and Where Does Fluid Loss Happen?

Fluid loss commonly happens:

- When disconnecting a hydraulic tool or accessory from the main system

- When reconnecting under residual pressure

- In mobile equipment, like tractors, skid steers, or excavators, especially during frequent tool changes

- In high-pressure systems, where fluid can spray out when pressure isn’t equalized

It’s not just about a few drops. In large systems or repeated daily connections, this fluid loss can add up to liters over time, leading to cost, mess, and risk.

Why Is Fluid Loss a Problem?

- Environmental Risk: Spilled hydraulic oil can contaminate soil and water, especially in agriculture, forestry, and marine applications.

- Workplace Safety: Oil on the floor is a slipping hazard. High-pressure spray during disconnection can also pose injury risks.

- System Efficiency: Air entering the system during disconnection can reduce efficiency or damage components.

- Cost: Hydraulic fluid is expensive. Frequent topping off leads to unnecessary operating costs.

- Cleanliness: In sensitive environments like food processing or clean rooms, even small leaks are unacceptable.

How Do Flat Face Quick Couplings Prevent Fluid Loss?

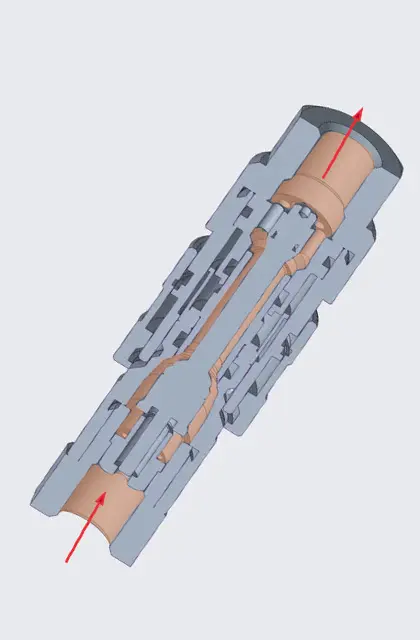

Flat face quick couplers, also known as no-spill couplers, are engineered to seal completely before disconnection and connect without external leakage. Here’s how they achieve it:

- Flat sealing surfaces on both male and female halves reduce gaps and crevices where fluid could leak.

- Internal valves stay closed until the connection is nearly complete — and close quickly before separation.

- Low air inclusion design reduces the chance of air entering the system when connecting.

- The smooth flat face is easy to wipe clean, reducing the chance of contaminants entering during connection.

Because of these features, flat face couplers are ISO 16028 compliant, the standard for non-spill hydraulic couplings.

Additional Benefits of No-Spill Couplers

- Cleaner operation: Ideal for mobile equipment that’s operated in clean environments (landscaping, turf maintenance, etc.).

- Reduced downtime: No need to clean up spills or top off fluid levels constantly.

- Better for high-pressure tools: Prevent pressure bursts or spray when connecting under residual pressure.

- Safer: Reduces exposure to hot or pressurized oil during maintenance or tool changes.

Where Are Flat Face Couplers Commonly Used?

- Agriculture: Tractors, harvesters, and skid steers

- Construction: Excavators, attachments, and hydraulic breakers

- Forestry and logging

- Industrial cleaning equipment

- OEM machinery and maintenance operations

Final Thoughts

If your application requires frequent hydraulic connections or operates in sensitive or high-risk environments, flat face quick couplers are the smart choice. They protect the system, the user, and the environment by significantly reducing — or completely eliminating — fluid loss during operation.

Whether you call it no-spill, dry-break, or minimal fluid loss, the principle remains the same: a better, cleaner, safer hydraulic connection.