Choosing the Right Seal Ring for Quick Couplings: Materials, Applications, and Temperature Resistance

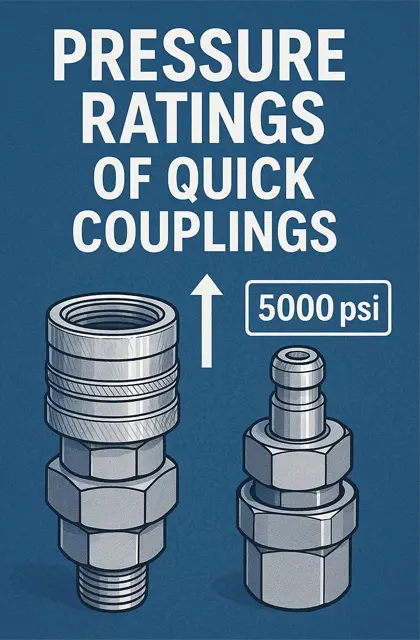

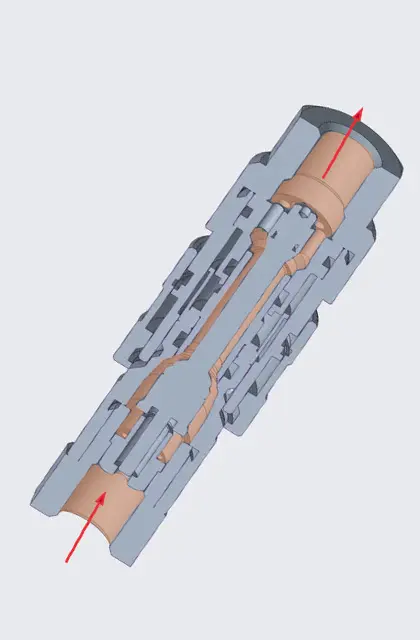

When it comes to hydraulic or pneumatic quick couplings, the seal ring (also known as the O-ring or gasket) plays a critical role in ensuring a leak-free and reliable connection. While often overlooked, the seal material must be carefully selected based on the fluid type, temperature, and operating environment. In this post, we’ll walk you […]